Thermaltake consistently delivers innovative PC components‚ and the Argent K5 exemplifies this. Recent releases‚ like the TT RGB PLUS 3.0 software‚ enhance user control and customization options for a premium gaming experience.

Overview of the Argent K5

The Thermaltake Argent K5 RGB is a gaming keyboard designed for enthusiasts seeking both performance and aesthetics. Building upon Thermaltake’s established case designs – like the expansive Tower 600 – the K5 integrates seamlessly into a broader TT RGB PLUS ecosystem. Released alongside software updates like TT RGB PLUS 3.0‚ it offers enhanced control over lighting and macros.

The keyboard aims to provide a customizable experience‚ evidenced by compatibility with various Thermaltake cases and accessories. Recent product lines‚ such as the AX Series‚ demonstrate Thermaltake’s commitment to scalable‚ high-performance builds‚ a philosophy reflected in the K5’s feature set.

Key Features and Specifications

The Argent K5 RGB boasts full-color RGB lighting‚ customizable via TT RGB PLUS 3.0 software‚ offering preset effects and custom profile creation. It features anti-ghosting and N-key rollover for reliable input during intense gaming sessions. Onboard memory allows for profile storage‚ ensuring personalized settings are readily available.

Recent Thermaltake releases‚ including the G6 Direct Drive Racing Wheel‚ highlight their focus on premium hardware. The K5’s specifications include adjustable polling rates and compatibility with Thermaltake cases like the Tower 600‚ enhancing the overall user experience.

Unboxing and Package Contents

Thermaltake prioritizes a premium unboxing experience. Expect a well-protected keyboard and included accessories‚ ready for immediate setup and customization with TT RGB PLUS 3.0.

What’s Included in the Box

Upon opening the Thermaltake Argent K5 package‚ users will find the keyboard itself‚ carefully encased in protective foam. A detachable USB-C cable is included for connecting the keyboard to your PC‚ ensuring a reliable connection. Alongside the cable‚ a quick installation guide provides essential setup instructions.

Furthermore‚ Thermaltake includes keycap pullers‚ facilitating easy keycap removal for cleaning or customization. Finally‚ a branded Thermaltake sticker is a nice addition for enthusiasts. The packaging is designed to protect the components during shipping and presents a premium unboxing experience‚ reflecting Thermaltake’s commitment to quality.

Initial Inspection and Components

A thorough inspection of the Thermaltake Argent K5 reveals a robust build quality. The keyboard chassis feels solid‚ indicating durable construction. The keycaps exhibit a smooth texture and clear legends. The detachable USB-C cable is braided‚ enhancing its durability and preventing tangling.

Visually‚ the RGB lighting elements are immediately apparent‚ promising vibrant customization. Examining the underside reveals rubber feet for stable placement. The included keycap puller is constructed from plastic‚ sufficient for standard keycap removal. Overall‚ the components demonstrate Thermaltake’s attention to detail and quality control.

Setting Up the Argent K5

Connecting the Argent K5 is straightforward via USB-C; Installing TT RGB PLUS 3.0 unlocks full customization‚ while driver updates ensure optimal performance and compatibility.

Connecting the Keyboard

Establishing a connection with the Thermaltake Argent K5 is a remarkably simple process‚ designed for immediate usability. The keyboard utilizes a standard USB-C connection‚ ensuring broad compatibility with modern desktop and laptop systems. Simply plug the USB-C cable‚ included in the package‚ into an available USB-A port on your computer.

The system should automatically recognize the keyboard‚ initiating the necessary driver installation if prompted. For optimal performance and to unlock the full range of features‚ particularly RGB lighting control and macro programming‚ it’s recommended to install the TT RGB PLUS 3.0 software suite – detailed in the following section.

Software Installation (TT RGB PLUS 3.0)

To fully utilize the Thermaltake Argent K5’s capabilities‚ installing TT RGB PLUS 3.0 is crucial. Download the latest version from the official Thermaltake website. Run the installer and follow the on-screen prompts‚ accepting the license agreement and choosing your preferred installation directory.

This upgraded software platform‚ released in 2025‚ offers optimized control over RGB lighting‚ macro assignments‚ and keyboard customization. Ensure your system meets the minimum requirements before installation for a seamless experience; A restart may be required to complete the process.

Driver Installation and Updates

Typically‚ the Thermaltake Argent K5 is plug-and-play‚ but for optimal performance and access to advanced features‚ driver installation is recommended. TT RGB PLUS 3.0 often includes necessary drivers during installation. However‚ check the Thermaltake support website for dedicated keyboard drivers or firmware updates.

Regularly updating drivers ensures compatibility and resolves potential issues. The software will usually prompt you for updates‚ or you can manually check within the TT RGB PLUS 3.0 application. Keeping drivers current guarantees a smooth and responsive gaming experience.

Customizing RGB Lighting

TT RGB PLUS 3.0 software unlocks extensive RGB control for the Argent K5‚ offering preset effects and the ability to create personalized‚ vibrant lighting profiles.

Using TT RGB PLUS 3.0 for Lighting Control

TT RGB PLUS 3.0 serves as the central hub for managing the Argent K5’s RGB illumination. After installation‚ the software automatically detects the keyboard‚ granting access to a comprehensive suite of customization options. Users can select from a wide spectrum of colors‚ adjust brightness levels‚ and control lighting speed. The intuitive interface allows for per-key customization‚ enabling unique lighting schemes tailored to individual preferences.

Beyond basic color adjustments‚ TT RGB PLUS 3.0 facilitates synchronization with other Thermaltake RGB components within the ecosystem‚ creating a unified and immersive lighting experience across your entire setup. The upgraded software platform provides optimized performance and enhanced stability for seamless control.

Preset Lighting Effects

The Thermaltake Argent K5‚ managed through TT RGB PLUS 3.0‚ boasts a diverse library of pre-configured lighting effects. These include static color modes‚ breathing effects‚ wave patterns‚ and reactive lighting that responds to keystrokes. Users can quickly cycle through these presets to find an effect that suits their gaming style or aesthetic preferences.

Popular options like “Rainbow” and “Ripple” offer vibrant and dynamic illumination‚ while more subtle effects like “Breath” provide a calmer ambiance. These presets offer a convenient starting point for customization‚ allowing users to easily enhance their gaming setup without complex programming.

Creating Custom Lighting Profiles

TT RGB PLUS 3.0 empowers users to design personalized lighting profiles for the Thermaltake Argent K5. Within the software‚ each key can be individually assigned a color and effect‚ enabling intricate and unique lighting schemes. Users can save multiple profiles tailored to different games or moods.

The software’s intuitive interface allows for easy experimentation with color palettes and dynamic effects. Profiles can be exported and shared‚ fostering a community of creative lighting designs. This level of customization ensures a truly personalized gaming experience.

Macro Programming

The Argent K5‚ paired with TT RGB PLUS 3;0‚ facilitates complex macro creation. Record and assign key sequences for streamlined in-game actions and enhanced productivity.

Assigning Macros to Keys

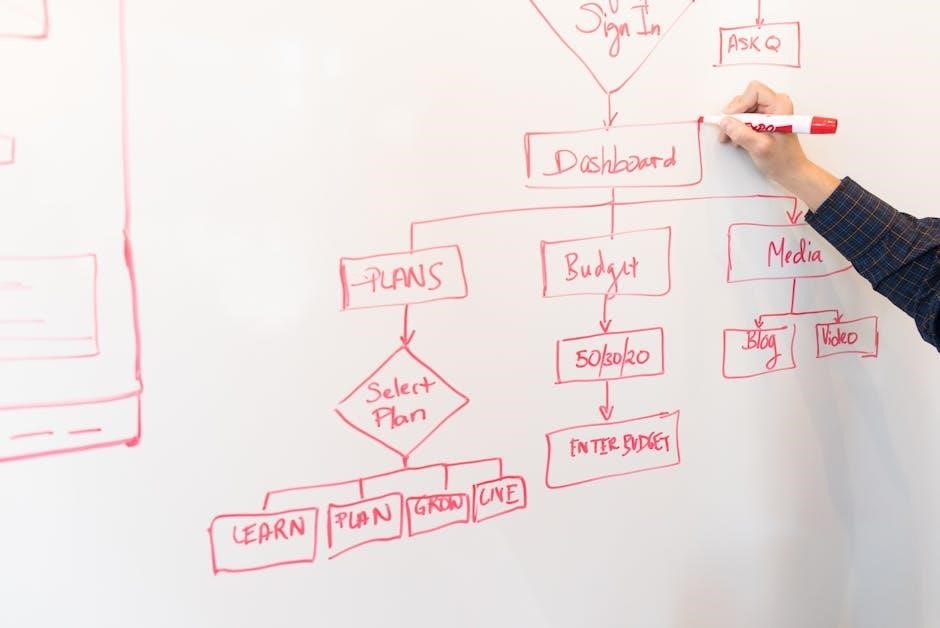

Utilizing TT RGB PLUS 3.0‚ assigning recorded macros to the Argent K5’s keys is a straightforward process. Within the software interface‚ navigate to the macro assignment section. Select the desired macro from your saved list‚ then choose the specific key on the keyboard to which you want to bind it.

The software allows for single-key assignments or complex key combinations. Confirm your selection‚ and the macro will be instantly linked to that key. This enables quick access to frequently used commands‚ complex actions‚ or customized shortcuts during gameplay or daily tasks‚ boosting efficiency and responsiveness.

Macro Recording and Editing

TT RGB PLUS 3.0 facilitates both macro recording and editing for the Argent K5. Initiate recording within the software‚ and every keystroke‚ delay‚ and action will be captured. After recording‚ you can meticulously edit the macro sequence. Adjust timings‚ delete unwanted actions‚ or insert new commands with precision.

The software provides a clear‚ visual representation of the macro‚ simplifying the editing process. Save your refined macros with descriptive names for easy identification and future use. This level of control ensures your macros perfectly match your specific needs and preferences.

Macro Storage and Management

The Thermaltake Argent K5‚ paired with TT RGB PLUS 3.0‚ offers robust macro storage and management capabilities. The software allows saving numerous custom macros‚ categorized and named for easy access. Utilize onboard memory to store frequently used macros directly on the keyboard‚ enabling use across different systems without software dependency.

Import and export macro profiles for backup or sharing with other users. Efficiently organize your macros‚ streamlining your gaming and productivity workflows. This ensures quick access to essential commands‚ enhancing your overall experience with the Argent K5.

Key Remapping and Customization

TT RGB PLUS 3.0 empowers users to remap keys and create custom bindings on the Argent K5‚ tailoring the keyboard to individual preferences and workflows.

Remapping Function Keys

The Argent K5’s function keys (F1-F12) are readily customizable through the TT RGB PLUS 3.0 software. Users can assign a wide range of functions‚ including multimedia controls‚ application launching‚ and even complex macros‚ directly to these keys. This allows for quick access to frequently used commands without interrupting gameplay or workflow. The intuitive interface simplifies the remapping process‚ offering a user-friendly experience.

Beyond standard functions‚ the software supports assigning system commands‚ opening specific websites‚ or executing custom scripts. This level of customization ensures the keyboard adapts perfectly to the user’s needs‚ enhancing productivity and convenience. Profiles can be created and saved for different applications or games.

Creating Custom Key Bindings

The Argent K5‚ powered by TT RGB PLUS 3.0‚ allows complete customization of key bindings beyond the function keys. Any key on the keyboard can be reassigned to perform a different function‚ offering unparalleled control. This is particularly useful for gamers seeking optimized control schemes or users requiring specialized shortcuts. The software’s drag-and-drop interface makes the process straightforward and intuitive.

Users can bind keys to keyboard strokes‚ mouse actions‚ multimedia controls‚ or even launch applications. Multiple profiles can be saved‚ allowing for quick switching between different key configurations tailored to specific games or tasks. This feature enhances both gaming performance and overall productivity.

Advanced Features

The Argent K5 boasts anti-ghosting and N-Key Rollover‚ ensuring every keystroke registers accurately. Onboard memory stores profiles‚ and polling rate adjustments optimize performance.

Anti-Ghosting and N-Key Rollover

The Thermaltake Argent K5 is engineered with advanced anti-ghosting and N-Key Rollover (NKRO) technology. This crucial feature guarantees that every single keypress is accurately registered‚ even when multiple keys are pressed simultaneously.

Traditional keyboards can suffer from “ghosting‚” where certain key combinations aren’t recognized due to hardware limitations. NKRO eliminates this issue‚ providing a competitive edge in fast-paced gaming scenarios. Whether executing complex commands or rapid key sequences‚ the Argent K5 ensures reliable input‚ preventing missed actions and frustrating errors. This responsiveness is vital for a seamless and immersive gaming experience.

Onboard Memory for Profile Storage

The Thermaltake Argent K5 boasts integrated onboard memory‚ allowing users to save and access customized profiles directly on the keyboard itself. This eliminates the need for constant software re-configuration when moving the keyboard between different computers or gaming setups.

Store personalized RGB lighting schemes‚ macro assignments‚ and key remappings directly onto the Argent K5. This feature ensures your preferred settings are always available‚ providing a consistent and tailored gaming experience regardless of the system being used. It’s a convenient solution for LAN parties and traveling gamers.

Polling Rate Adjustment

The Thermaltake Argent K5 allows users to adjust the polling rate‚ influencing the keyboard’s responsiveness. A higher polling rate – typically 1000Hz – means the keyboard reports its status to the computer more frequently‚ resulting in reduced input lag and potentially faster reaction times in games.

Through the TT RGB PLUS 3.0 software‚ gamers can select from various polling rate options to optimize performance based on their system and preferences. While a higher rate is generally preferred‚ it can consume more system resources. Experiment to find the ideal balance for a smooth gaming experience.

Troubleshooting Common Issues

Addressing potential problems with the Argent K5 is straightforward. Common concerns include recognition issues‚ RGB malfunctions‚ and macro functionality – easily resolved with provided guidance.

Keyboard Not Recognized

If your Thermaltake Argent K5 isn’t recognized‚ begin by verifying the USB connection. Ensure it’s securely plugged into a functioning USB port on your computer – try a different port if necessary. A restart of your system can often resolve temporary connection glitches.

Next‚ confirm that the TT RGB PLUS 3.0 software is correctly installed and running in the background. Check Device Manager within your operating system to see if the keyboard appears‚ and if any driver errors are reported. If it’s listed with an error‚ attempt to update or reinstall the drivers. Finally‚ test the keyboard on another computer to isolate whether the issue lies with the keyboard itself or your primary system.

RGB Lighting Malfunctions

Experiencing RGB issues with your Argent K5? First‚ ensure the TT RGB PLUS 3.0 software is up-to-date‚ as updates frequently address lighting bugs. Within the software‚ verify the selected lighting profile hasn’t become corrupted or defaulted to an incorrect setting. Try switching to a different preset to see if the problem persists.

If the issue continues‚ a USB port change might help‚ as some ports provide more stable power for RGB. A system restart can also resolve temporary software conflicts. If individual keys aren’t lighting up‚ check for keycap issues or potential hardware faults.

Macro Issues

Are your Argent K5 macros not functioning as expected? Begin by confirming the macro is correctly assigned to the desired key within the TT RGB PLUS 3.0 software. Double-check the recorded macro sequence for errors – even a single incorrect keystroke can cause failure. Ensure sufficient onboard memory is available for macro storage.

If macros work inconsistently‚ try reducing the macro’s complexity or length. Conflicts with other software can also occur; temporarily disable background applications to isolate the problem. Re-recording the macro is often a quick solution.

Maintenance and Care

Regular cleaning and proper storage will maximize the lifespan of your Argent K5. Avoid liquids and harsh chemicals; a soft‚ dry cloth is ideal for upkeep.

Cleaning the Keyboard

Maintaining a clean Argent K5 ensures optimal performance and longevity. Before cleaning‚ disconnect the keyboard from your computer to prevent accidental key presses or electrical damage. Use a soft‚ dry microfiber cloth to gently wipe down the keycaps and chassis‚ removing dust and debris. For stubborn dirt‚ slightly dampen the cloth with water‚ ensuring it’s not dripping wet.

Avoid harsh chemicals‚ solvents‚ or abrasive cleaners‚ as these can damage the keycaps or finish. For hard-to-reach areas between the keys‚ consider using a can of compressed air to blow out dust and particles. Never disassemble the keyboard for cleaning purposes‚ as this may void the warranty and cause damage. Regular‚ gentle cleaning will keep your Argent K5 looking and functioning its best.

Proper Storage

When storing your Thermaltake Argent K5‚ protect it from potential damage. Ideally‚ store the keyboard in its original packaging to shield it from dust‚ impacts‚ and moisture. If the original packaging isn’t available‚ use a padded bag or box. Avoid storing the keyboard in extreme temperatures or humidity‚ as this can affect its components.

Do not place heavy objects on top of the keyboard during storage‚ as this could damage the keycaps or internal mechanisms. Ensure the storage location is free from liquids and potential spills. Proper storage will help maintain the keyboard’s condition and ensure it’s ready for use when you need it.

Thermaltake Product Ecosystem

Thermaltake’s diverse range‚ including cases like the Tower 600 and AX Series‚ seamlessly integrates with the Argent K5 via the TT RGB PLUS ecosystem.

Compatibility with Thermaltake Cases (Tower 600‚ AX Series)

The Thermaltake Argent K5 is designed to aesthetically complement a wide array of Thermaltake chassis‚ notably the expansive Tower 600 and the versatile AX Series. These cases‚ available in classic black and snow white finishes‚ provide ample space for high-performance builds.

The AX Series‚ supporting E-ATX to XL-ATX motherboards‚ offers scalable solutions‚ while the Tower 600 allows for extensive radiator setups and storage configurations. Integrating the Argent K5 with these cases creates a cohesive and visually striking gaming setup‚ enhanced by synchronized RGB lighting through TT RGB PLUS.

Integration with TT RGB PLUS Ecosystem

The Thermaltake Argent K5 seamlessly integrates into the comprehensive TT RGB PLUS ecosystem‚ benefiting from the upgraded TT RGB PLUS 3.0 software platform. This all-in-one solution provides centralized control over all compatible Thermaltake products‚ allowing for synchronized lighting effects and customized profiles.

Users can leverage the software’s optimized interface to manage RGB illumination‚ create stunning visual displays‚ and coordinate lighting across their entire Thermaltake setup‚ including cases‚ coolers‚ and fans‚ for a truly immersive experience.

Warranty Information

Thermaltake provides warranty coverage for the Argent K5‚ details of which are available online. Claims require proof of purchase and adherence to stated terms.

Warranty Coverage Details

Thermaltake’s warranty for the Argent K5 RGB gaming keyboard typically covers defects in materials and workmanship under normal use. The standard warranty period is often two years from the original purchase date‚ though this can vary by region. Coverage includes component failures affecting functionality‚ such as key switches or RGB lighting.

The warranty does not cover damage resulting from misuse‚ accidents‚ modifications‚ or unauthorized repairs. Normal wear and tear‚ including keycap shine‚ is also excluded. To initiate a claim‚ retain your proof of purchase and contact Thermaltake support through their website for specific instructions and an RMA (Return Merchandise Authorization) number.

How to Claim Warranty

To initiate a warranty claim for your Thermaltake Argent K5 RGB‚ first gather your original proof of purchase – a receipt or invoice is essential. Visit the official Thermaltake website and navigate to the support section. Locate the RMA (Return Merchandise Authorization) request form and complete it accurately‚ detailing the issue.

You’ll need to provide the keyboard’s serial number and a clear description of the defect. Once approved‚ you’ll receive an RMA number and shipping instructions. Carefully package the keyboard and ship it to the designated Thermaltake service center.

Technical Support and Resources

Thermaltake’s website offers extensive support‚ including FAQs and forums. Direct assistance is available through their support channels for Argent K5 inquiries.

Thermaltake Website and Support Forums

Thermaltake’s official website serves as a central hub for all Argent K5 resources. Users can access detailed product information‚ downloadable drivers (including updates for TT RGB PLUS 3.0)‚ and the comprehensive digital manual. The dedicated support section provides troubleshooting guides addressing common issues like keyboard recognition or RGB malfunctions.

Furthermore‚ Thermaltake’s active online forums foster a community where users can share experiences‚ seek assistance from fellow gamers‚ and receive support from Thermaltake staff. These forums are invaluable for resolving complex problems and discovering community-driven solutions related to the Argent K5 and its software.

Contacting Thermaltake Support

For personalized assistance with your Argent K5 RGB keyboard‚ Thermaltake offers multiple support channels. Direct contact can be initiated through their official website‚ utilizing the online support request form for detailed inquiries. Email support is also available‚ ensuring a documented communication trail.

Additionally‚ Thermaltake maintains an active presence on social media platforms‚ providing a quick avenue for basic support questions. For warranty claims or more complex technical issues‚ referencing your purchase details and the Argent K5’s serial number is crucial for efficient resolution.